K-MINE Custom Solution

IoT Platform

The K-MINE solution connects to various elements of the mining process, such as equipment, plants, and corporate departments, and receives real-time data from them.

This data is analyzed against historical data to deliver the analytics via the web application.

Our solution can be combined with the K-MINE End-to-End Planning solution to enhance enterprise workflow optimization if required.

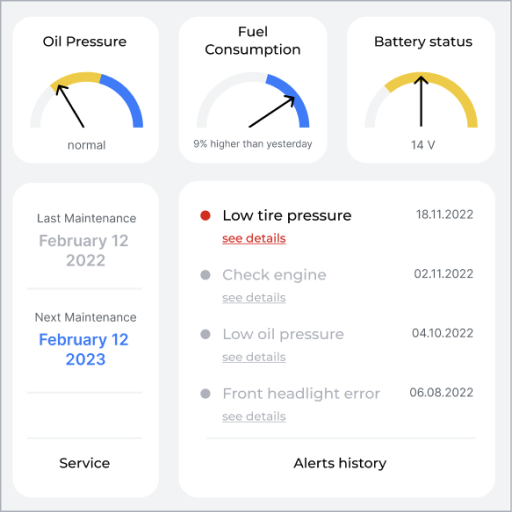

Asset Monitoring and Management

We can connect all equipment to a single interface where it can be assigned to different departments. Using this interface, our clients can monitor the condition of the equipment in real time.

This functionality makes it possible to plan equipment maintenance far in advance and perform preventive maintenance to avoid wasting money.

Resources Monitoring and Prediction

Our solution can help your business use this data to generate resource consumption reports, compare current energy and material prices, and analyze the data for optimization.

Safe Environment for Employees

In addition to the equipment, we can also integrate with sensors and systems to monitor the areas where people are present and collect data on air quality, emissions, personal health, and other environmental safety monitoring data.

Using appropriate equipment, we can establish rules for equipment shutdown in specific scenarios.

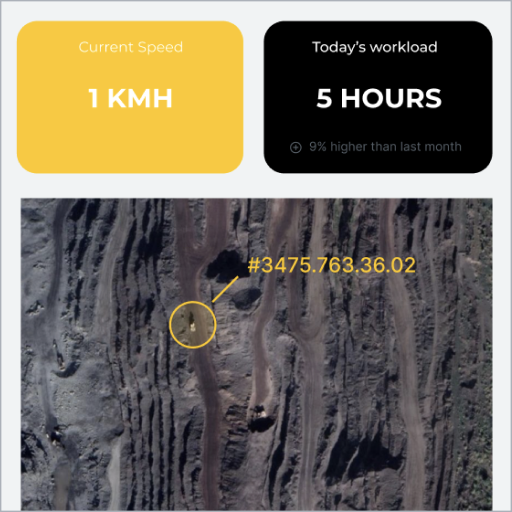

Asset Tracking in Real Time

Our solution also helps to track the location of vehicles in real time and send notifications in case of overspeeding or entry into high-risk areas.

You can easily access the data in K-MINE to display it in the mine design or view it on a map in the web interface.

Production Monitoring

We can connect not only mining equipment but also any other equipment and processes, from development to production, enabling you to control the entire process from the mine or open pit to the market.

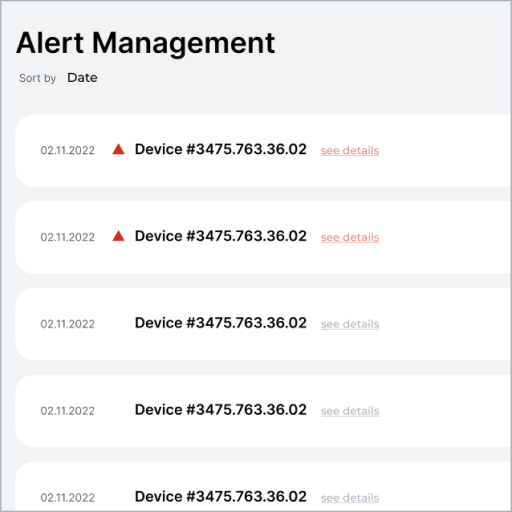

Notifications and Reports

With K-MINE, you can create customized dashboards and reports for different departments to receive the information you need in real time, with options to filter and create additional notifications and alerts to ensure performance safety and efficiency.

Moreover, you can generate historical reports for equipment analysis and more accurate procurement planning.

You can generate the following reports:

· Asset location · Cycle time · Cost-per-load · Conveyor load · Fill rate · Average energy production rate · Electricity purchased · Energy storage

· Average dump time · Fuel level · Battery status · Tire Pressures · Oil Pressures · Emissions · Working hours Maintenance duration · Downtime

· CO Level · Temperature · NOx levels · Water level · Heart rate · Employee Safety Score · Etc

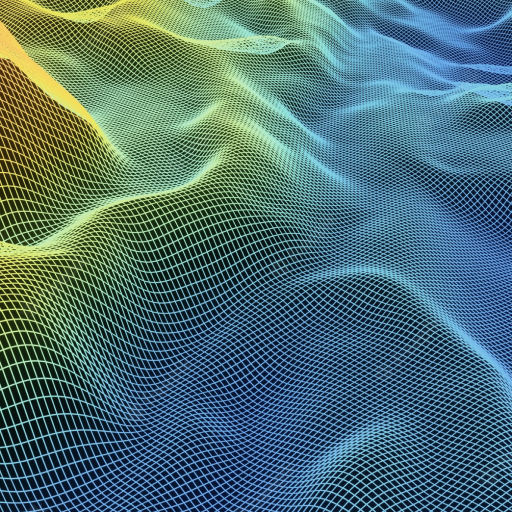

Heat Mapping

While the system is in operation, we can also draw special maps with data processed in real time and identify issues in areas of your enterprise, using both real-time and historical data.

Advanced Analytics

In addition to real-time data analysis, you can use the data for a long-term equipment performance history, among other applications.

This information is essential for AI and machine learning models to forecast economic and safety performance.

Key Takeaways

1. We can integrate with any data source, third-party systems, sensors, and equipment.

2. You can use the data in any K-MINE module.

3. You can use the data for digital twinning or short-term planning optimization.

Frequently Asked Questions

What kind of licenses does K-MINE provide and how much do they cost?

K-MINE offers two types of licenses: monthly or annual subscriptions and perpetual licenses. Please contact the K-MINE team to learn about the pricing for each module.

How can information be transferred from one module to another?

K-MINE is a standalone application with a single database, so no data transfer is necessary. Different teams can access data according to their user rights.

Is K-MINE cloud-based software?

No, K-MINE is a desktop application. However, upon request, our team can install it on a Windows server and set up a cloud infrastructure.