Mining Industry Software / Pit Optimizer

Open Pit Optimization

A strategic planning tool that facilitates informed decision-making that significantly affects cash flows over the long term.

Identify the most profitable blocks and create nested pit shells based on the price adjustment factor and other parameters. This module uses the advanced PseudoFlow algorithm, derived from the Lerchs-Grossmann concept. With K-MINE’s built-in tools, users can quickly determine the optimal final boundary, create long-term schedules, perform sensitivity analyses, and compare pit designs. Conduct a thorough analysis of results to manage cash flows and evaluate field prospects effectively.

Strategic Planning Tool

The most important

component of the

solution-making

process.

Comprehensiveness

A wide range of features

for accurately recreating existing and planned project conditions.

Consistency

A step-by-step

approach to ensure you don’t overlook anything.

Transparency

Confident decision-making

supported by a wide range

of resulting information.

Optimization Process

Analyze the obtained results of the optimization process in deep detail with our inbuilt features. You can visualize any group of blocks that corresponds to a specified price coefficient factor.

Track the optimal pit progression just like this. Also, use wireframe creation to represent your results as physical results. It could be a simple wireframe or a smoothed one.

Final Pit Limits Obtaining

Thanks to the Lerch-Grossman algorithm you can receive as many nested pits as it’s required according to price coefficient factor. Create copies of a scenario, and change parameters to define the most profitable case.

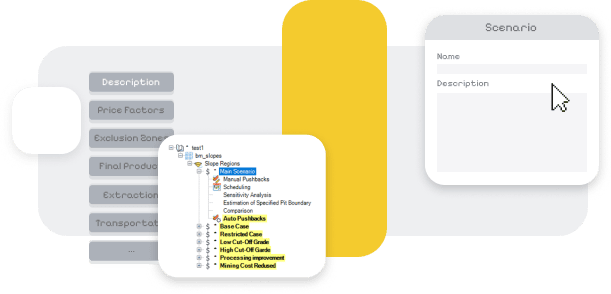

Step-by-Step Scenario Creation

Create scenarios easily and sequentially. The step-by-step approach provides understanding and easy learning of this hard from the first point of view process.

Create as many scenarios as it’s required, compare results, and choose the more profitable case.

Results of Optimization

Receive final pit limits according to the specified price coefficient factor range. Create pit Shells based on resulting groups of blocks.

Include additional restrictions based on simple polylines that are easy to use, and specify necessary mining costs for specific regions.

Track the influence on your resulting economic model and the number of blocks included in the final result.

Results Analysis

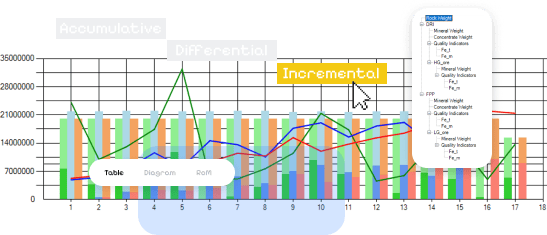

We can’t just leave you alone with the results of the optimization process, that’s why we created additional possibilities to identify the most profitable case. They are Charts and detailed tables, additionally, you can create cross-sections for detailed analysis.

Main Results of Optimization

Use Multiple options to analyze the obtained result.

Detailed Tables, Pre-configured Charts, Visible Groups of blocks corresponding to each result of the LG Algorithm, Create Cross-sections, etc…

Inbuilt Specific Abilities

Choose the final pit boundary that is optimal according to requirements. Use all available instruments for analysis to define the best option from many others. The maximal pit expansion, TheMai best NPV, Required Marginal Profit, maximum cash Flow, Highest profit, Optimal resources involvement, etc…

Use pre-configured templates in different modes of information display to define the best option.

Additional Possibilities

Thanks to our add-ones in the Pit Optimizer module we can provide Sensitivity Analysis to define the most influential peace of a plan, create Pushbacks for future planning, create Schedules, compare results, and analyze info.

Sensitivity Analysis

Make a sensitivity analysis with a couple of steps.

Analyze the influence on your economic part with multiple indicators. Try to define the most important from many others and optimize it to obtain the best results.

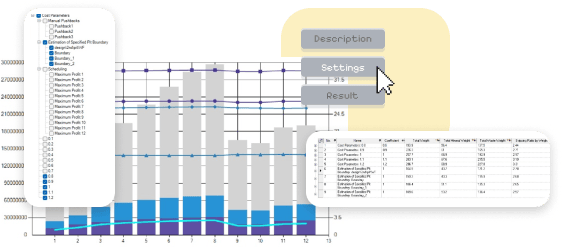

Pushback Creation

Split chosen final pit shell by specific Pushbacks in Automatic and Manual modes. The Automatic mode will try to define the best solution based on the NPV indicator and specified mining parameters. The Manual mode creates what are you asking for.

Combine both to define the optimal and mineable pushbacks.

Scheduling

Create long-term schedules with the belt method that is based on optimal pit shells and elevations on it.

Flexible tools to set searching parameters in combination with mining parameters provide the possibility to define the general and optimal mining sequence of the chosen pit shell.

Results Comparison

Compare different pit shells with the results of your obtained scenario. Load prepared designs and select them to define the optimal way to develop your mine.

We offer Mining Consulting!

K-MINE boasts extensive engineering experience and knowledge of our product capabilities, enabling mining companies to enhance their technical and economic performance, increase productivity, and boost profitability.

Frequently Asked Questions

What is the purpose of the Pit Optimizer?

The Pit Optimizer module is designed to help mining companies identify the most profitable pit boundaries and excavation strategies for open-pit mining. It calculates optimal boundaries by analyzing ore body distribution, extraction costs, and market factors, ensuring that only economically viable material is targeted.

Who should use the Pit Optimizer?

The Pit Optimizer is ideal for mining strategists, economists, and planners looking to enhance profitability in open-pit operations. It’s valuable for anyone responsible for high-level planning and economic assessments in open-pit projects.

How does the Pit Optimizer determine the optimal pit boundaries?

The Pit Optimizer uses algorithms that factor in ore grades, extraction costs, slope constraints, and market prices to outline pit boundaries that maximize profit. It automates the process of delineating economically feasible sections of the ore body, ensuring that only profitable material is included in the pit design.

Can the Pit Optimizer support iterative planning?

Yes, the Pit Optimizer is designed for iterative analysis. Users can adjust parameters and immediately see how changes affect the profitability and shape of the pit. This iterative approach is particularly useful when evaluating multiple market scenarios or cost structures.

How does the Pit Optimizer integrate with other K-MINE modules?

The Pit Optimizer works seamlessly with other K-MINE modules like Geology and Mining Monitoring, enabling users to incorporate geological models and track key parameters as part of their pit optimization workflow. This integration ensures that economic planning aligns with geological and operational data for a more holistic approach.

Why choose the Pit Optimizer over traditional economic models?

Unlike traditional economic models, the Pit Optimizer provides a dynamic, data-driven solution that continually adapts to input changes, producing precise boundary recommendations based on profitability. This automation saves time and reduces the risk of overlooking profitable sections, making it a reliable choice for enhancing open-pit profitability.