K-MINE Module

Ventilation

- for underground mining engineers involved in design and simulation.

- for specialists responsible for maintaining the atmosphere in the mine.

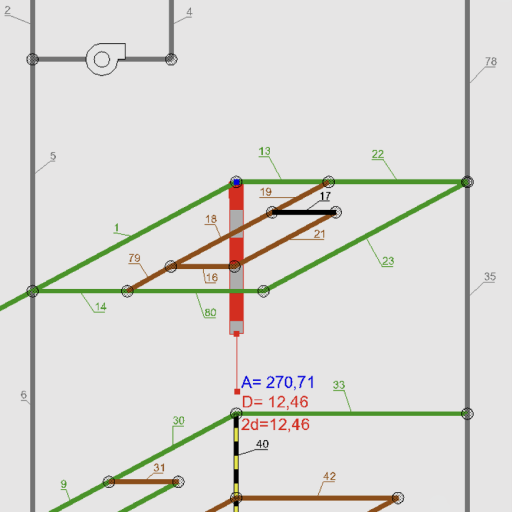

Creating and Entering Ventilation System Parameters

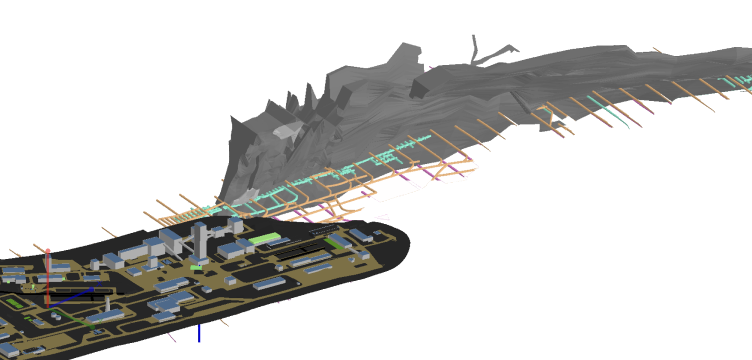

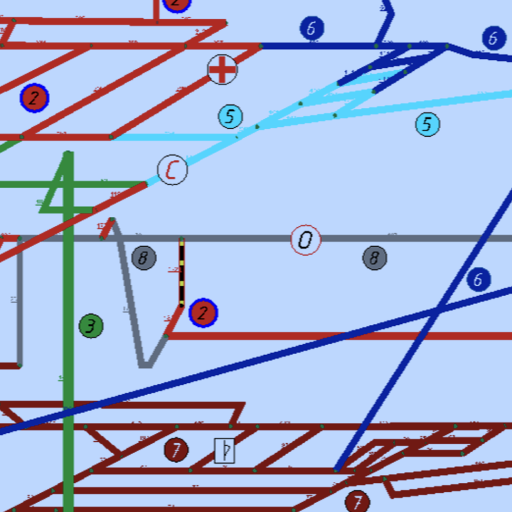

A flow graph of the mine ventilation system is the source of data for the calculations, including:

- Digital model of underground workings

- Main and local ventilation fans

- Ventilation subsystems, air inlets/outlets, air dams, ventilation doors, thermal depression

Use the system to:

- Create a ventilation system quickly, with demonstrable deliverables and fewer parameters set for underground workings

- Enter the data needed for the calculations while constructing objects.

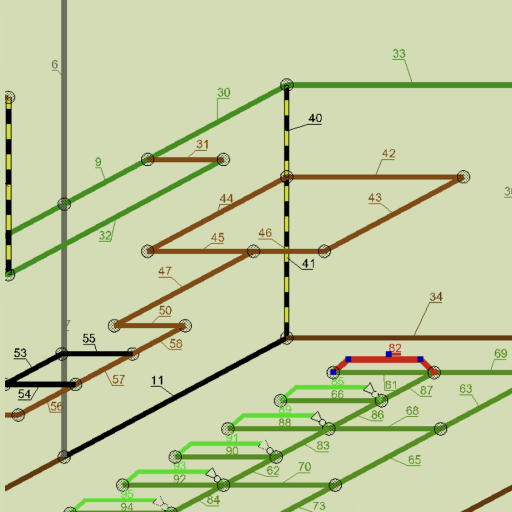

Creating a Ventilation System: Key Features

- Use existing templates to create underground workings

- Create new user objects and legends, or configure the existing ones

- Edit visualization parameters for workings quickly

- Add new properties and parameters for workings and other objects in accordance with user requirements

- Manipulate objects in the graphic environment

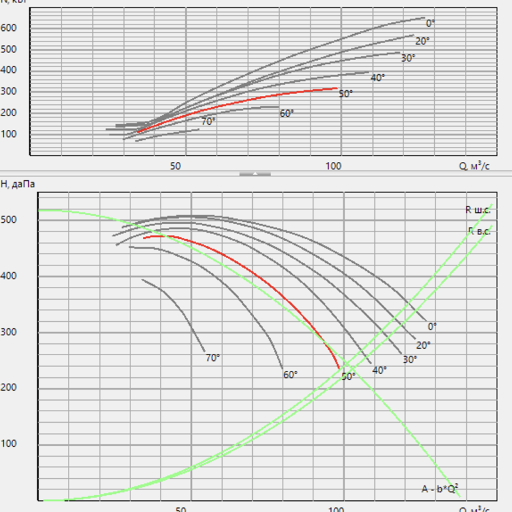

Selecting Fan Modes

- Build a database for mail and local ventilation fans

- Utilize the graphic database with fan specifications

- Determine optimal parameters for fan systems, aiming for minimum power consumption

System Application

K-MINE: Ventilation calculates air distribution, analyzes various ventilation system options, and assesses mine air pollutants.

Calculation of Gas Concentrations in an Emergency

- Calculation of gas concentrations in underground workings in the event of a fire for the existing ventilation system

- Forecasting potential accident consequences

- Modeling the performance of various ventilation options in an emergency

Graphic Display Features of the Emergency Response Plan (ERP)

- Create legends in the graphic environment as required by regulations

- Display the graphic information from ERP according to the reference number of a working

- Apply the ERP color scheme to the workings based on their reference numbers

- Configure, edit, and save numerous user-specific lists of the ERP color scheme for various options

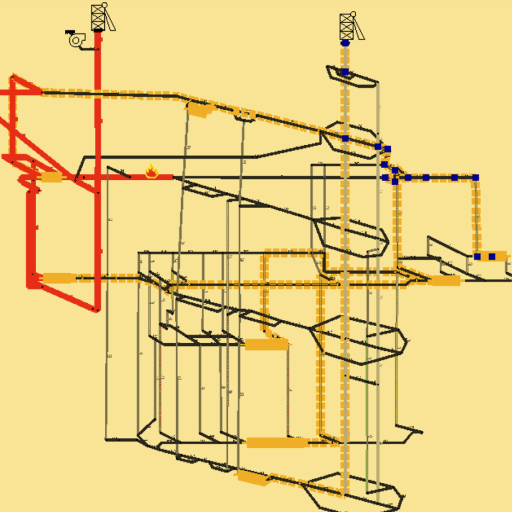

Exit Routing

1. Determine the shortest exit route to evacuate miners from a hazard area:

- from a specific working

- from all workings where miners are present during an emergency

2. Determine the travel time and distance in safe and gassy underground workings

3. Visualize exit routes for personnel and rescuers

4. Adjust escape routes by including or

5. Excluding inaccessible workings

Frequently Asked Questions

What kind of licenses does K-MINE provide and how much do they cost?

K-MINE offers two types of licenses: monthly or annual subscriptions and perpetual licenses. Please contact the K-MINE team to learn about the pricing for each module.

How can information be transferred from one module to another?

K-MINE is a standalone application with a single database, so no data transfer is necessary. Different teams can access data according to their user rights.

Is K-MINE cloud-based software?

No, K-MINE is a desktop application. However, upon request, our team can install it on a Windows server and set up a cloud infrastructure.