K-MINE Module

Scheduling

- for mining engineers and experts in mine planning.

- for other professionals responsible for the tactical planning of mining operations.

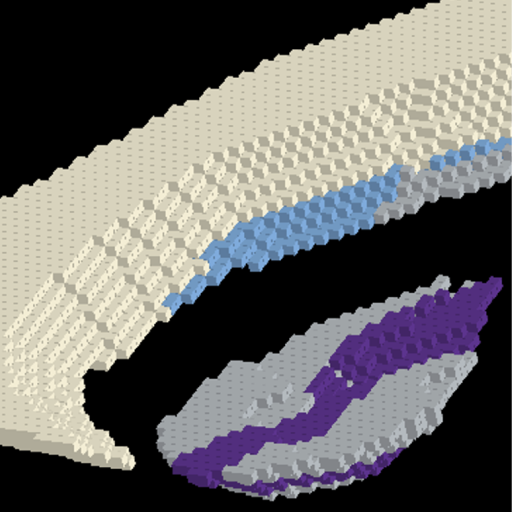

Automatic Search for the Optimum Sequence of Mined Rock Extraction

K-MINE enables the automatic search for the optimal sequence of mined rock extraction from open–pit or surface mine.

This module allows you to effortlessly create a mining schedule for any time period. Additionally, you can establish a mine development scenario with predetermined extraction sequences and forecast mining progress over any time horizon.

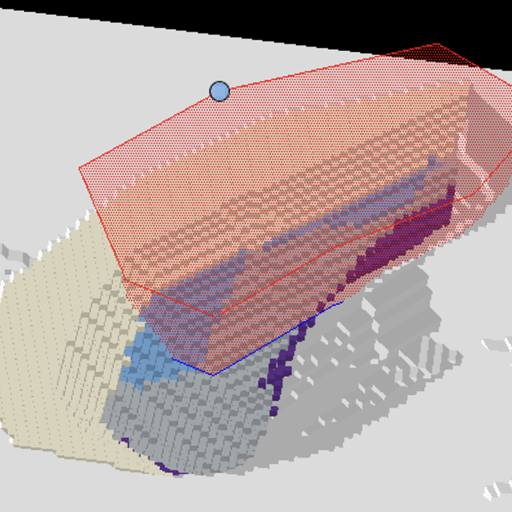

Identifying Scheduling Areas

With the K-MINE Scheduling module, you can identify scheduling areas using several methods:

- By manually drawing polygons.

- By utilizing an existing field in the block model of a deposit.

- By limiting blocks within a block model using standard functionality.

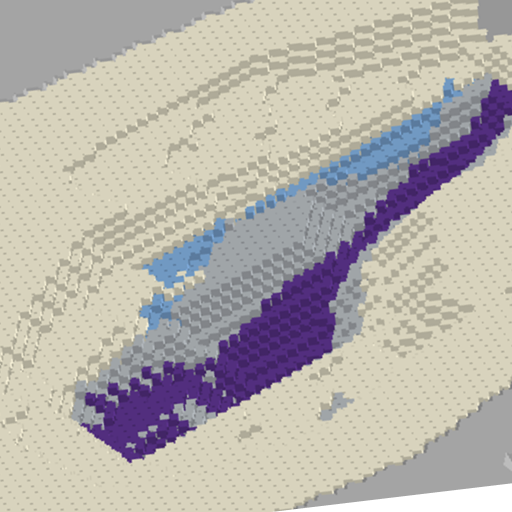

Status of Mining Operations Monitoring

When setting up a scenario to predict mining progress, you will get detailed information, at a specific stage of plan development, on:

- Face position

- Status of mining operations

- Total mined rock volume that has been or will be extracted before the completion.

This way, you can monitor the status of the mining operations on a daily basis.

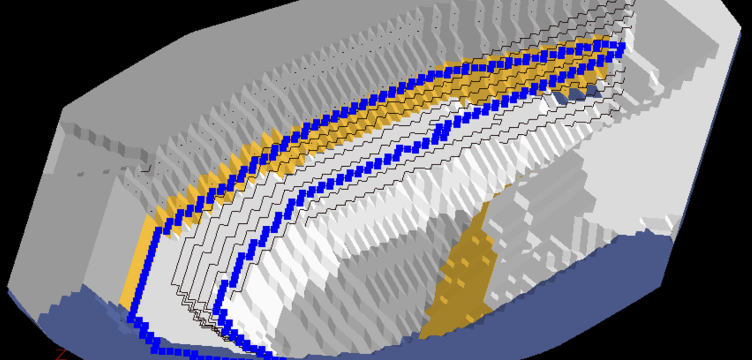

Wireframes and Polylines

The deliverables of the K-MINE Scheduling module include mining surfaces/wireframes and polylines for the scheduling period. You can download polylines from the design to sublayers by periods, areas, or levels.

All these elements are part of the software environment and can, therefore, be easily used for further operations.

Schedules Customization

The scheduling process is automatic, but you can customize the schedules as you like. Target parameters, area settings, and outputs per area are used to find the best solution.

To get a better picture, you can visualize the completed scheduling periods in the K-MINE operating environment.

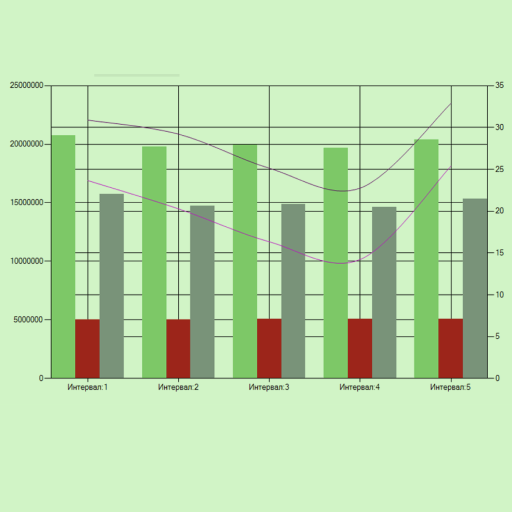

Customizable Graphs

For mining schedule analysis and reporting purposes, the K-MINE Scheduling module visualizes output data as customizable graphs.

Moreover, you can download the output table data in a variety of formats, including Excel, and analyze it where necessary.

Frequently Asked Questions

What kind of licenses does K-MINE provide and how much do they cost?

K-MINE offers two types of licenses: monthly or annual subscriptions and perpetual licenses. Please contact the K-MINE team to learn about the pricing for each module.

How can information be transferred from one module to another?

K-MINE is a standalone application with a single database, so no data transfer is necessary. Different teams can access data according to their user rights.

Is K-MINE cloud-based software?

No, K-MINE is a desktop application. However, upon request, our team can install it on a Windows server and set up a cloud infrastructure.